The Great Wall: Design & manufacture

The most expensive Chinese film in history is about to hit the big screen. The Great Wall, a US-China co-production from Legendary, China Film Group, Le Vision Pictures and Atlas Entertainment, with acclaimed director Zhang Yimou at the helm, has a Kiwi connection. Wellington creative design and practical effects facility Weta Workshop contributed concept design and manufactured thousands of weapons, props and costume components for the film at the company’s home base on the Miramar Peninsula.

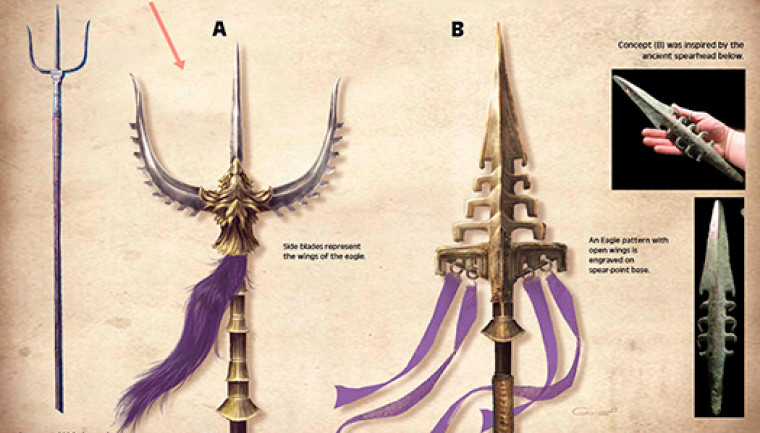

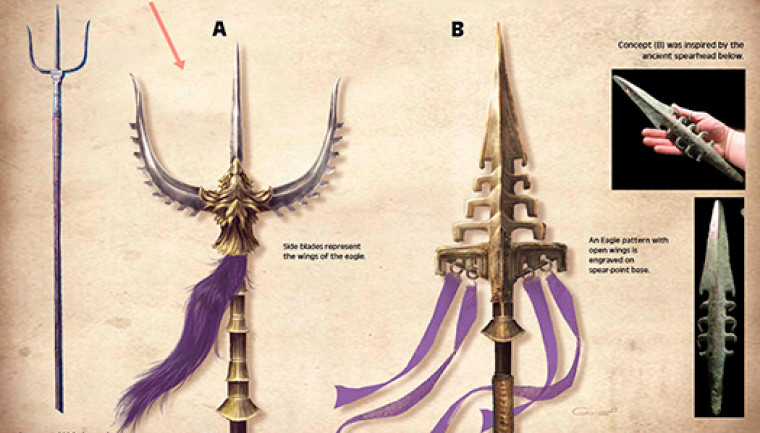

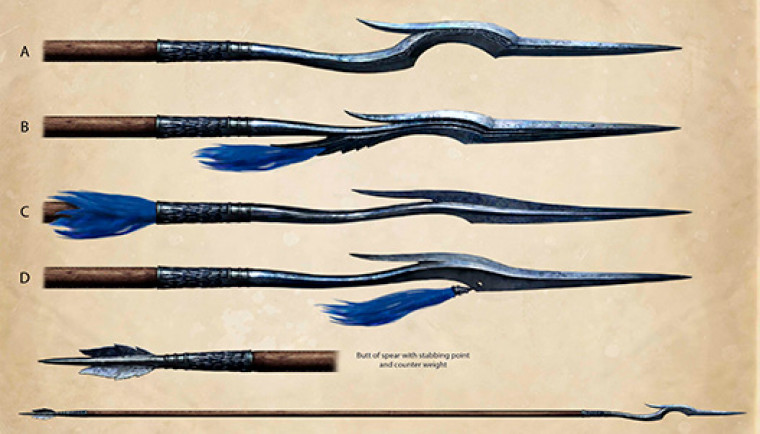

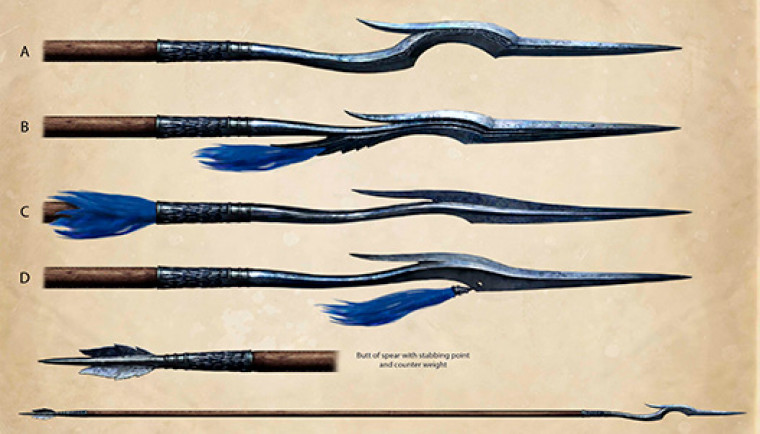

Working closely with The Great Wall’s own design team, the Weta Workshop design studio rendered over a thousand concepts for creatures and weapons, including shields, spears, axes, daggers, swords and arrows, all saturated in rich colour. The teams worked collaboratively on the concepts, ferrying designs through to the Workshop floor when they were ready for manufacture. Although The Great Wall is a work of fantasy, its Song Dynasty-era setting meant that the designs had to embody a sense of historical realism. Says Design Studio Project Manager Tasha Guillot:

It is always a wonderful challenge for us to explore trying to create something beautiful, striking and exciting in a fantasy realm while feeling inspired and grounded within the realms of a historic period. The team relished the opportunity for The Great Wall and, I think, excelled in achieving this balance for the designs within this dynasty in Chinese history.

A particular challenge presented itself to the Design Studio: visualising the taotie. An ambiguous ancient motif that appears throughout Chinese mythology, the taotie were to appear in The Great Wall as living, breathing creatures. To help define how the taotie would look and move, the Workshop’s concept design team experimented with motion tests and explored ways to give even the strangest of body parts a cohesive anatomy.

You have to think about it in three dimensions and how it would move and what it would sound like. Just how detailed we had to get with our approach was a challenge, but also really rewarding.

The enormous scope of the project was an incredible opportunity for Weta Workshop’s manufacturing division, whose part in the project mirrored the vast scale of the production back in Qingdao, China. Artists and technicians from more than seven departments fabricated 6500-odd props and weapons for the film’s armies and three of its lead actors. This was, by all accounts, one of the Workshop’s most colossal projects to date.

Our first task was to dissect The Great Wall script and work in with the film’s Prop Master to determine the types of weapons needed, and how we would build them for the action scripted. Would they be used in stunt work? Which props would be filmed up close? We quickly realised that this film called for just about every type of screen weapon imaginable.

With the cast of The Great Wall numbering in the many hundreds, Weta Workshop’s experience on large-scale fantasy productions such as The Lord of the Rings, The Hobbit, and Legendary’s 2016 blockbuster Warcraft came into play. Derived from a 3D modelling process, stunt weapons were cast in lightweight foam; ‘hero’ weapons in hard urethane or aluminium. VFX weapons were manufactured with ‘green’ or missing elements in order for VFX to treat the interaction of the weapon with the creatures of the story. Several hundred spears were produced, each one up to four metres tall – so big that they could not be shipped in one piece.

Leather components came courtesy of Weta Workshop’s costume department, whose artisans lent their talents to quivers and scabbards, leather wraps for the pommels of swords, and complex rigging systems that were tested on set in China and refined at the Workshop in Miramar.

Of the thousands of props produced by the Workshop, 1900 alone were arrows: one of the most complex, intricate and time-consuming parts of the project. Says Holly: “For this highly technical job, we had the privilege of working with master fletcher Jan Koszler. Once our crew had hand-painted and dyed the feathers, they were delivered, along with their shafts, to Jan, who carefully fletched each individual arrow – a massive task.” The shafts, complete with fletch, were returned to the Workshop where the crew cast on arrow tips in urethane, aluminium or foam, before painting and threading each end.

A sci-fi fantasy monster-adventure action epic set in historical China: an extraordinary premise for a movie and a fantastic opportunity for Weta Workshop! That a sizeable part of the biggest Chinese film ever made has been produced in a small suburb of Wellington, New Zealand, is a terrific thing for us all to celebrate. Our manufacturing and design teams have really outdone themselves with what they have been able to achieve for this film.

As large as its part in the project was, the 65,000 man hours that Weta Workshop spent on the film was a mere fraction of the effort involved in bringing this epic cross-cultural co-production to the screen. The armies of The Great Wall, armed with Weta Workshop’s arsenal, will battle a terrifying evil on international screens in February 2017.

Get in touch

If you’re looking for a creative company to design or build your next project, we’d love to chat.

- 17+ creative departments

- Over 30 years’ experience

- Highly awarded

- Design to manufacture

- Innovation and creativity

- Government incentives may apply